IXYS Corporation announced an expansion of its Ultra Junction Power MOSFET product line: 650V X2-Class Power MOSFETs with fast body diodes. With on-resistance as low as 17 mΩ and current ratings ranging from 22A to 150A, these devices are optimized for soft-switching resonant-mode power conversion applications.

The intrinsic fast body diodes of the MOSFETs display very soft recovery characteristics, minimizing electromagnetic interference (EMI) especially in half or full-bridge switching topologies. With low reverse recovery charge and time, the body diodes can be utilized to make sure that all the energy are removed during high-speed switching to avoid device failure and achieve high efficiency.

Like other Ultra Junction MOSFETs from IXYS, these new devices have been developed using a proprietary process technology resulting in Power MOSFETs with significantly reduced on-resistance and gate charge. They also exhibit a superior dv/dt performance and are avalanche rated as well. Thanks to the positive temperature coefficient of their on-state resistance, they can be operated in parallel to meet higher current requirements.

Suitable applications include resonant-mode power supplies, high intensity discharge (HID) lamp ballast, ac and dc motor drives, dc-dc converters, robotic and servo control, battery chargers, 3-level solar inverters, LED lighting, and Unmanned Aerial Vehicles (UAVs).

These new 650V X2 Power MOSFETs with HiPerFET™ body diodes are available in the following international standard size packages: TO-220, TO-263, SOT-227, TO-247, PLUS247, TO-264, and PLUS264.

Some example part numbers include IXFA22N65X2, IXFH46N65X2, IXFK120N65X2, and IXFN150N65X2, with drain current ratings of 22A, 34A, 120A, and 145A, respectively.

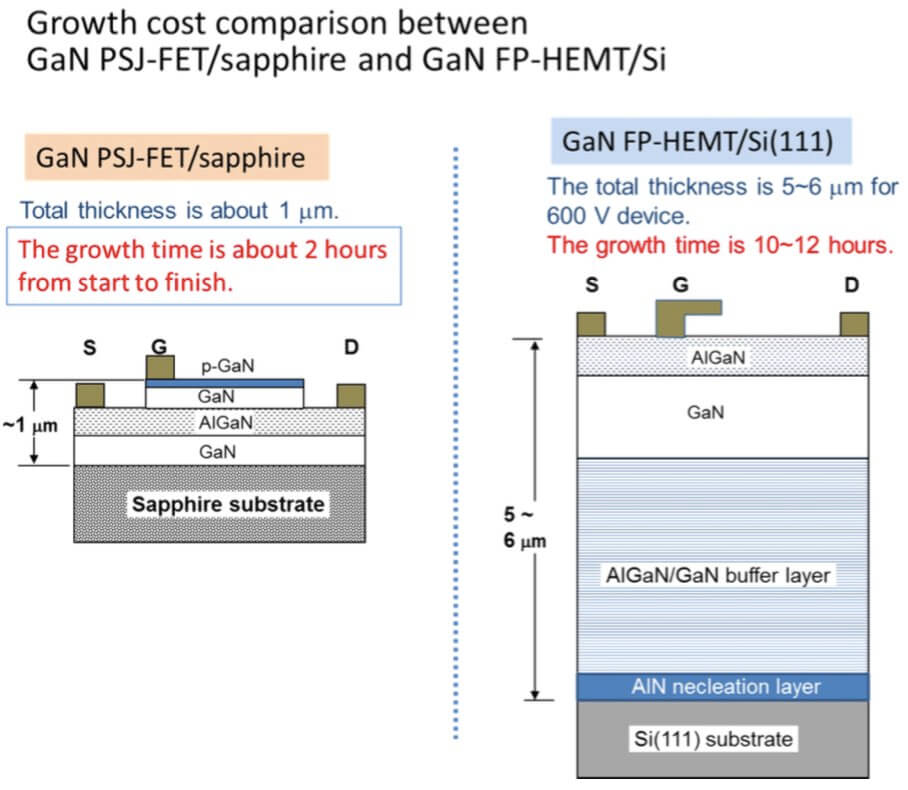

Sapphire substrate is also a common platform for GaN-LED production and the growth runs successively without chamber-cleaning. On the other hand, the growth on Si substrate needs chamber-cleaning prior to the deposition to avoid the unwanted chemical reactions between GaN and Si interface. The chamber-cleaning takes extra time and cost. As a whole, the throughput for GaN PSJ-FET/sapphire growth is roughly ten times larger than that of the GaN FP-HEMT/Si growth.

Sapphire substrate is also a common platform for GaN-LED production and the growth runs successively without chamber-cleaning. On the other hand, the growth on Si substrate needs chamber-cleaning prior to the deposition to avoid the unwanted chemical reactions between GaN and Si interface. The chamber-cleaning takes extra time and cost. As a whole, the throughput for GaN PSJ-FET/sapphire growth is roughly ten times larger than that of the GaN FP-HEMT/Si growth.