TDK-Lambda has been working on this product almost a year. The release has been delayed several times due to design issues to be solved before having a reliable and high quality product. PFH500F-28 has been released in November, without a great press and marketing shout outs. It was displayed at Electronica 2018, with no sign advertising for GaN devices inside, as one would expect. This is the first application of GaN power devices in this type of power supplies in module form factor.

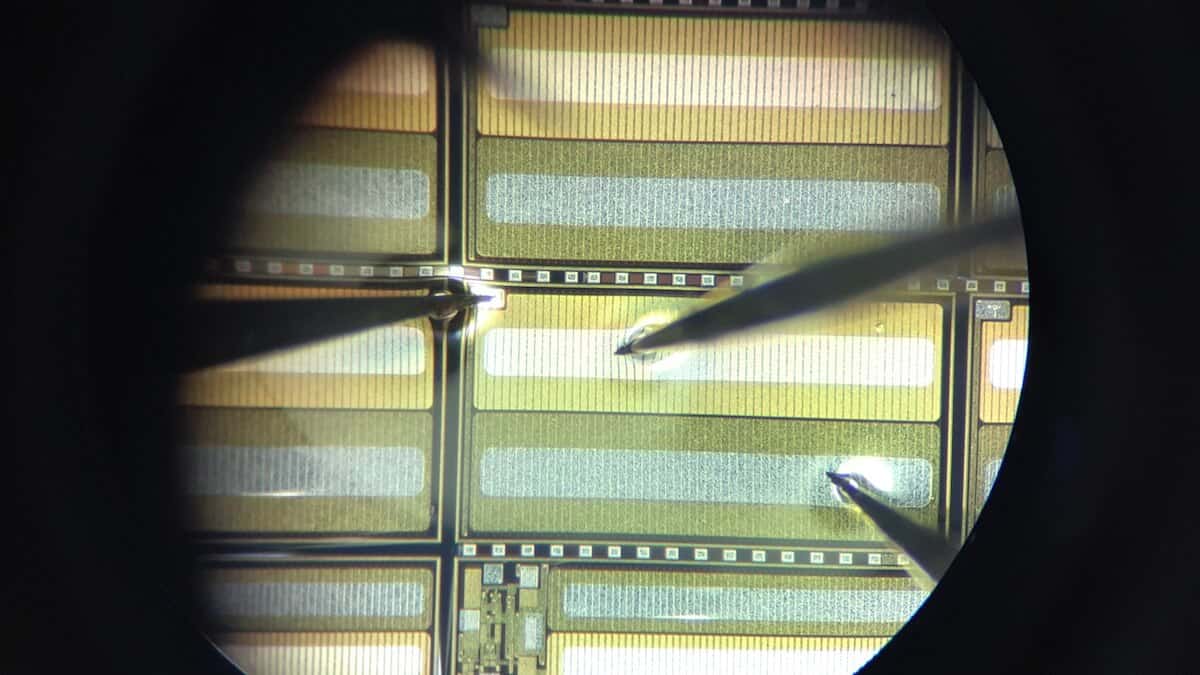

TDK-Lambda 500W power supply using Transphorm GaN devices for the PFC stage

About the inside, TDK-Lambda used GaN transistors in a ‘bridge-less’ PFC stage. This delivers an efficiency of 98% for this stage, resulting in a peak efficiency of 92% for the overall power supply. The advantages of GaN transistors here is not only on efficiency but also on form factor: These power supplies are made to stay small and very flat. TDK says they have been able to reduce the board space by 25% thanks to GaN devices in this case. They target a limited amount of small volume industrial applications, where customers prefer to outsource the power supply stage and focus on their added value.

According to the marketing team at TDK-Lambda, the power supply could have been more efficient, at the cost of more components counts, a higher price, and potentially a bigger form factor due to limited board space. The GaN components used are from Transphorm (cascode D-Mode devices), that can provide the high switching speed necessary, together with the expected reliability.

The PFH500F is targeting off-the-shelf power supply markets as LED signage, communications, broadcast, test and measurement according to TDK.

Specifications:

- Input: 85 to 265Vac

- Output: 22.4 to 33.6V with 18A at 28V

- PMBus control for output adjustment.

TDK says other output voltages will be available later this year.

We expect other manufacturers as Recom, or Cosel (through their recent acquisition PRBX) to release similar power supplies based on GaN devices in a near future. The market volume for such power supplies is quite small but still an opportunity for GaN to grow and show its used and reliable.