Electric car makers are to become Smart-grid system makers

In June 2015, PointThePower.com made an analysis of electric car manufacturing business and the link that will be made with energy grid and energy storage. This analysis is now becoming true. After Tesla, Daimler and Audi, it’s now Nissan’s turn to announce that they will use second-hand batteries for home energy storage.

So if you missed the analysis, here is a synthesis: Back in time, Alstom, Siemens, GE, Mitsubishi Electric and few other huge companies became both electric transport system makers and energy production or storage system makers. This happened because the core competency to target was Power electronics, and they mastered the topic. They either started with transportation systems to come to energy, or the other way round.

Now that the car market is becoming electric, and that energy production is coming down to consumer level, the same thing is happening. Car makers master “consumer power range” electric systems. So, you will soon see electric car makers becoming full energy supply-chain players, at lower power levels compared to Alstom and Siemens.

We performed this analysis almost one year ago: It’s still available in full here.

For more info about Nissan/Eaton solution, just read below:

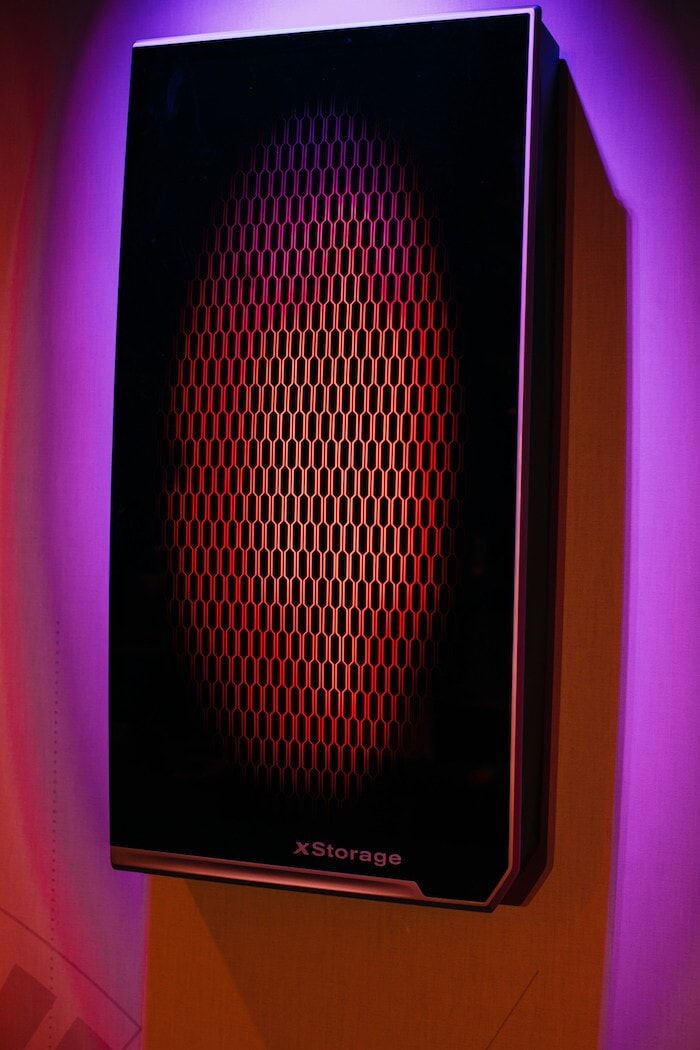

Nissan and Eaton release “xStorage”

Nissan and Eaton, have joined forces to unveil a new residential energy storage unit. Available to pre-order from September 2016, the “xStorage” solution will give consumers possibility to control how and when they use energy in their own homes.

Connected to residential power supply or renewable energy sources such as solar panels, the unit can charge up when renewable energy is available or energy is cheaper (e.g. during the night) and release that stored energy when demand and costs are high.

The home energy storage system also provides a back-up solution to consumers, ensuring that the lights never go out. Moreover, customers can sell stored energy back to the grid when demand and costs are high.

It’s providing a sustainable “second life” for Nissan’s electric vehicle (EV) batteries after their first life in cars is over, the new unit is powered by twelve Nissan EV battery modules and has the potential to revolutionize the way people manage energy usage in their own home, providing added flexibility and multiple cost savings.

“The collaborative development between Eaton and Nissan enabled us to optimize development and production costs and deliver a well-integrated offer to consumers. Our system will be provided to end-users completely ready to use, with all required elements including cabling and installation by a certified professional, at a starting price of €4,000 (£3200) for 4.2KWh nominal. Our policy is to avoid hidden extra costs and achieve a lower total cost of ownership than other major offers already announced.”

, said Cyrille Brisson, VP Marketing at Eaton Electrical EMEA.

The new xStorage system unveiled today marks the start of a longer-term commitment by Nissan and Eaton to widen the portfolio of energy storage solutions available to both private and commercial customers. Nissan and Eaton expect to sell more than 100,000 xStorage units within the next five years as the consumer appetite for this type of technology continues to grow.