GaN again: good news?

I remember reading a tribune on TI social blog about how much GaN discussions were exhausting these days. The author said that APEC 2015 was hammering with GaN. We have been talking about GaN over and over. And every year it’s the same thing. 2015 Rap Session at APEC concluded once more that “It’s here, it’s coming. It’s good. We need to use it.” The round-table captivated the audience, as usual, but it leads to the same talks and questions with the same kind of people. I understand it becomes exhausting. It’s too much, even for me. I would like Gallium Nitride devices to be out, used everywhere, and that we start talking about something else, like Diamond or carbon nanotubes. I wish we had passed the curve, and we were at the top of it and we were looking at something else.

But we are not there yet. We will still see a lot of GaN, but I hope and I think that we will see different GaN. Let me explain why such a theory.

Why we will see GaN again at APEC this year

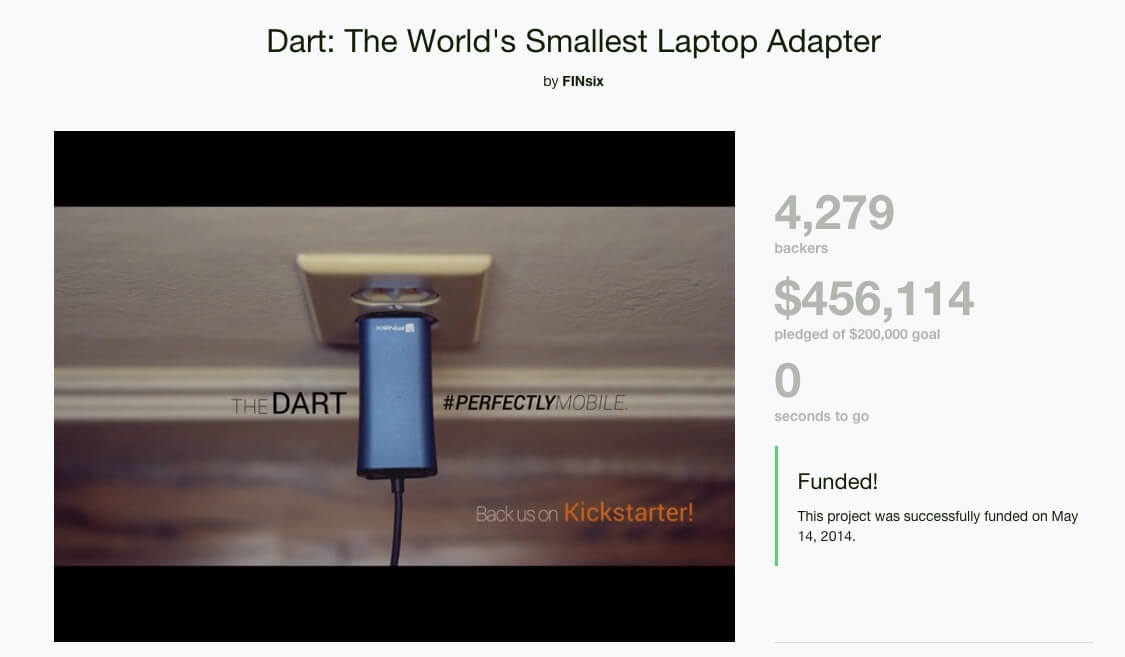

We already have device start-ups and bigger companies working on Gallium Nitride devices. We know the pros and cons. We know a lot about the devices themselves. So why would we still talk about that in 2016 at APEC? I wrote recently an article about why we still cannot find GaN in small power supplies (like Zolt and maybe FinSix). GaN devices will irrigate the market in the near future. You find all the analysis, explanations and some roadmap in the GaN Market Analysis report that we’re going to release next month. But there is still a missing thing: conversion systems (and the specialists that come with it).

And Point The Gap’s belief is that this is the next step for GaN. The step where you see big companies trying to use GaN devices, and where you see a few start-ups developing new types of systems. They work on new topologies, architectures, innovative passive components, PCB design or anything needed to make GaN or SiC deliver their best. This new era has started with FinSix back when it was still On-Chip Power and they were targeting LED power supply business. Now you also have Cambridge Electronics Inc. in Massachusetts, or Nordic Power Converter in Denmark.

You also have companies like Navitas Semiconductor, which, even though they are still in stealth mode and will probably present more during APEC, claim on their single page website that they work on GaN power ICs.

Why is Gallium Nitride good news

We all want a “GaN break ”. But it’s very good news. It means a new era is coming. Now we have companies designing systems using GaN, and innovating at conversion level. Until now, all the power conversion topologies we have developed and invented were aimed at using Silicon. It started with Silicon MOSFET, then IGBT, and Super Junction MOSFET came after that to push further the limits of Silicon. Today, the performance of Silicon has been exploited, and even if we can still improve Si devices, the gain is not as large compared to what it was 10 or 20 years ago. GaN devices are available for sampling and soon for production, and now that system designers have something to work on, I think we will watch them play with it.

Thus we will hear about GaN because we are still expecting system design (and maybe passive components design) to show us what it got.

I bet we will see a few start-up companies going out of stealth mode, and these companies won’t talk about GaN devices. They will blow our mind with GaN based conversion systems. To me, it’s a heck of a good news!

All of this will of course be included in our “GaN devices and applications in power electronics” report, to be released by April of this year.

What else than GaN ?

SiC systems (and a few devices too)

We can definitely expect more Silico-Carbide devices. We have seen and we are seeing more and more systems using SiC MOSFETs. Not much using SiC BJT or other FET. We expect this trend to keep going on. Avogy proved that we can expect GaN and finally see SiC. Maybe it will happen again. PV inverters, UPS, Air conditioning built around full-SiC power modules and discrete devices is to expect this year at APEC.

In addition to that, this is the first year Wolfspeed will attend APEC as « Wolfspeed », grouping ex-Cree Power & RF together with ex-APEI Inc. This would be a good time to announce new projects, joint work or even high-end products. APEI Inc being very good at military or Hi-rel applications.

Power stacks for high-voltage applications are mostly announced during PCIM in May in Nuremberg. I thick we will wait a few more months for these announcements.

Passive components, power stacks or new inverters ?

We will probably have some new stuff on this side. But it’s not easy to define what will be announced in which field. There are some things going-on about digital control. Integration of passive components or Power IC is also fields where we expect to see tome new things announced.

Only time will tell. PointThePower.com will attend. We will be pleased to meet with you. Drop us an e-mail and we will come to you.

Otherwise, stay tuned on the website and you will live APEC as if you traveled, there through our report to come right after the show !

We do have one Zolt charger at PointThePower.com but we don’t have the lab to tear it down… Our friends from

We do have one Zolt charger at PointThePower.com but we don’t have the lab to tear it down… Our friends from

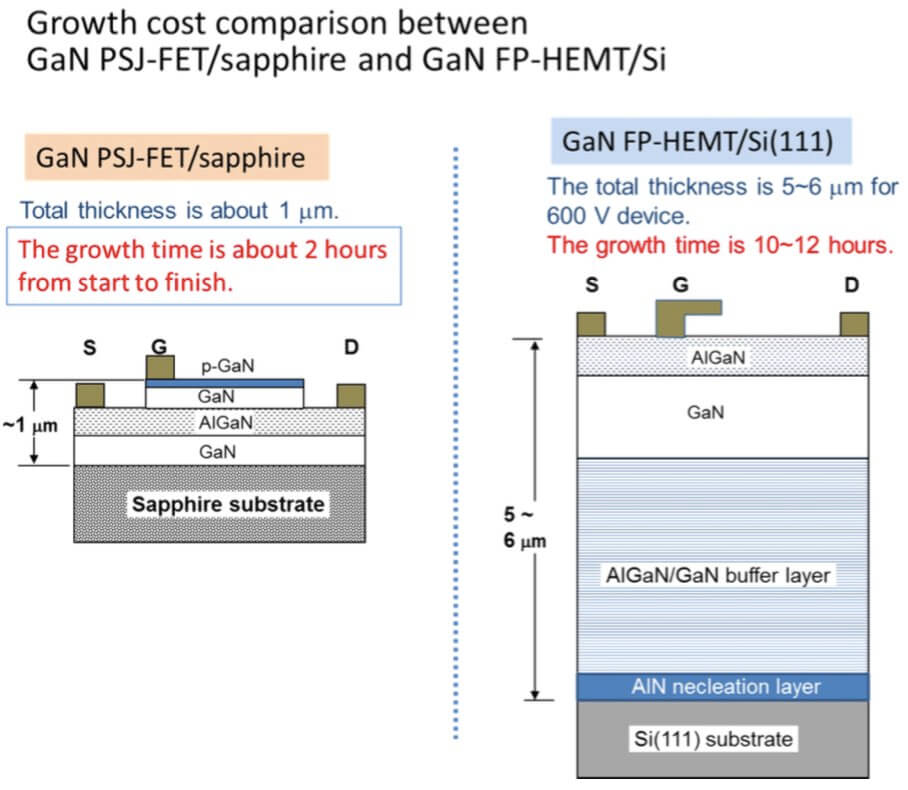

Sapphire substrate is also a common platform for GaN-LED production and the growth runs successively without chamber-cleaning. On the other hand, the growth on Si substrate needs chamber-cleaning prior to the deposition to avoid the unwanted chemical reactions between GaN and Si interface. The chamber-cleaning takes extra time and cost. As a whole, the throughput for GaN PSJ-FET/sapphire growth is roughly ten times larger than that of the GaN FP-HEMT/Si growth.

Sapphire substrate is also a common platform for GaN-LED production and the growth runs successively without chamber-cleaning. On the other hand, the growth on Si substrate needs chamber-cleaning prior to the deposition to avoid the unwanted chemical reactions between GaN and Si interface. The chamber-cleaning takes extra time and cost. As a whole, the throughput for GaN PSJ-FET/sapphire growth is roughly ten times larger than that of the GaN FP-HEMT/Si growth.