About the SiC MOSFETs modules in Tesla Model 3

[Update 02/07/2018: We know the packaging manufacturer and added the name to the article. Devices used are 650V SiC MOSFETs and not 1200V, as stated at first. Update 09/07/2018: Packaging supply chain has been further described.]

Tesla Model 3 is using Silicon Carbide MOSFETs for its main inverter. It is now confirmed from reverse engineering analyses from different expert companies (Munro Associates and System Plus Consulting).

From Si IGBT in TO-247 to SiC MOSFETs in molded package

PntPower missed an analyst publication from August 2017 stating that ST Microelectronics was selected as a main supplier for Tesla Model 3 thanks to its SiC MOSFET at 650V. ST Microelectronics, at the time, was among the most advanced companies in SiC MOSFETs with a 1200V device already available, but nothing confirmed that SiC MOSFETs would be used as main devices for Model 3 inverter. As a reminder we extensively searched and commented the use of IGBTs in TO-247 packages in Tesla’s previous cars: Roadster, Model S and Model X. This also confirms the technological jump and the serious willingness of Tesla to become a major manufacturer of electric cars. This kind of specific design and packaging in a car is similar to the evolution of Toyota in the Prius, in a quest to improve design, density and efficiency of the HEV’s best seller, year after year.

Plastic molding and Cu ribbon-bonding: The high standard for power devices packaging

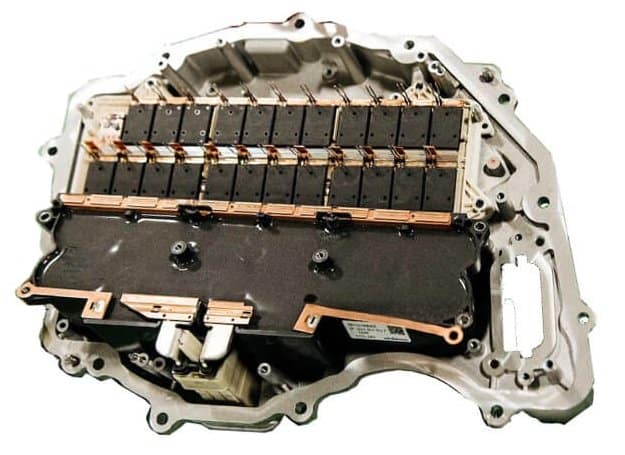

It is now confirmed that Tesla has been integrating SiC MOSFET based power modules from ST Microelectronics in Model 3 inverter. The modules are molded modules using copper ribbon-bonding for MOSFET connection. The SiC devices seems to be a 650V MOSFET at 100A made in Catania Fab (Italy), though no Automotive grade device is listed on ST Microelectronics website. The module is also very close to the most advanced technologies used today in Power Electronics packaging for automotive industry. It is to be compared with Mitsubishi electric J series TPM modules, with a cooling pad at the bottom and connections pin on the top. Packaging design has been made by a packaging expert company, based in the Netherlands, and called Advanced Packaging Center. Packaging production should be done by ST Microelectronics and/or their usual subcontractors for packaging.

Model 3 Main Inverter – Featuring 24 SiC MOSFET modules from ST Microelectronics (Source: Munro Assoc.)

1 000 000 SiC MOSFETs on the road

Tesla Model 3 manufacturing prediction from Bloomberg reach 38000 units as we speak (end of June 2018). 24 SiC MOSFET modules are used in each Model 3 inverter, this represents almost 1 Million ST Micro’s SiC MOSFETs on our roads. We will let the reader calculate the market it represents by putting its own price estimation on ST Micro’s modules.

Infineon will probably catch-up and quickly become a second source for Model 3 production in order to secure the supply-chain and follow the production ramp-up roadmap announced by Elon Musk.

Tesla made a technological jump between Model S and Model 3. It seems that Model S Power Electronic’s design objective was to quickly fulfill the power and performance requirements with off-the-shelf and available technology. On the other side, Model 3 designers might be more looking at mass-production and design and density optimization. It’s a clear sign that the Electric Vehicles market is starting to take the lead in Power Electronics innovation.

4x100A SiC NOSFET in parallel for one leg,estimated there is 100kW peak for the Model 3 inverter?

and how about the size of this inverter,is there any information on it?i assume it can exceed 40kW/L?

Hi LeonShan,

We looked for more information about the inverter volume but could not find it. We don’t have exact dimensions for this inverter, thus we don’t have the power density. We will keep your posted when we have more info.

Do u have the information about the MOSFET part number?

Hi Deepak,

It seems the part number is GK026. However this is not listed anywhere as an ST Microelectronics part. We know it’s a 600V SiC MOSFET, but cannot find more information about it.

Alex from PntPower